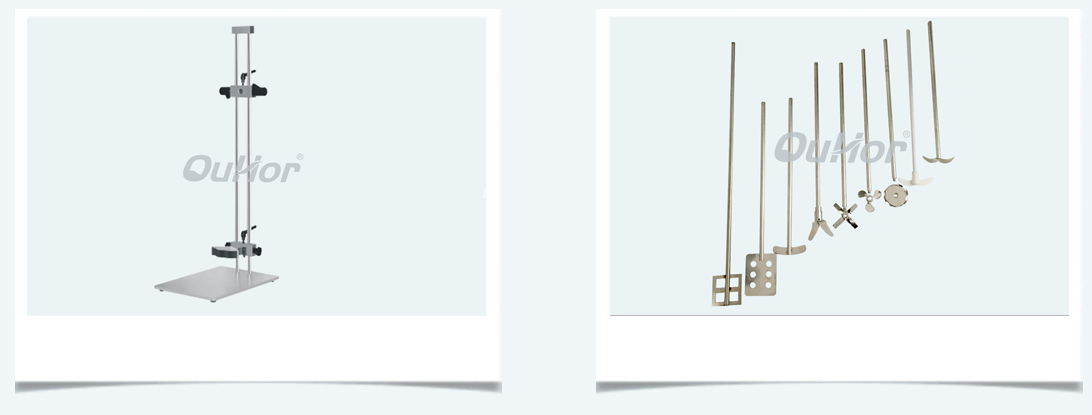

A200plus Digital Stirrer

Application

Used in biopharmaceutical, biochemical, food, nano materials, coatings, adhesives, daily chemicals, printing and dyeing, petrochemical, papermaking chemistry, and other fields.

Applicable to the mixing and dispersing processes of labora

点击咨询

Company advantage

-

Professional selection

Professional selection

Any equipment you choose, there is a one-to-one selection by professional engineers before purchase

Any equipment you choose, there is a one-to-one selection by professional engineers before purchase

Ensure that it fully meets your working conditions -

Focus on quality

Focus on quality

The company grasps the details at all times and always puts the highest quality of products first

The company grasps the details at all times and always puts the highest quality of products first -

Service first

Service first

The company cares about the user's feelings at any time, and quickly handles customer after-sales issues in a timely manner

The company cares about the user's feelings at any time, and quickly handles customer after-sales issues in a timely manner -

Professional in details

Professional in details

Win in the details, do a good job in products and services is our philosophy

Win in the details, do a good job in products and services is our philosophy